Thin-Film Solar Panels (2024 Guide)

In this EcoWatch guide on thin-film solar panels, you’ll learn:

- What are thin-film solar panels used for?

- What are the various types of thin-film panels?

- What is the difference between thin-film and traditional panels?

- What is the average cost of thin-film solar panels?

This guide has helped many homeowners discover the benefits and efficiency of thin-film solar panels and can help you make a decision on your first purchase. Let’s get started!

Each product and or company featured here has been independently selected by the writer. You can learn more about our review methodology here. If you make a purchase using the links included, we may earn commission.

What Are Thin-Film Solar Panels?

Like other solar panels, thin-film panels convert light energy into electrical energy by way of the photovoltaic effect. Unlike traditional systems, thin-film solar panels are very light and flexible second-generation cells. They are composed of multiple thin layers of photovoltaic, or PV, materials.

The layers are roughly 300 to 350 times thinner than standard silicon, which makes the technology ideal for portable devices. Each cell is made of three main parts: photovoltaic material, a conductive sheet and a protective layer.

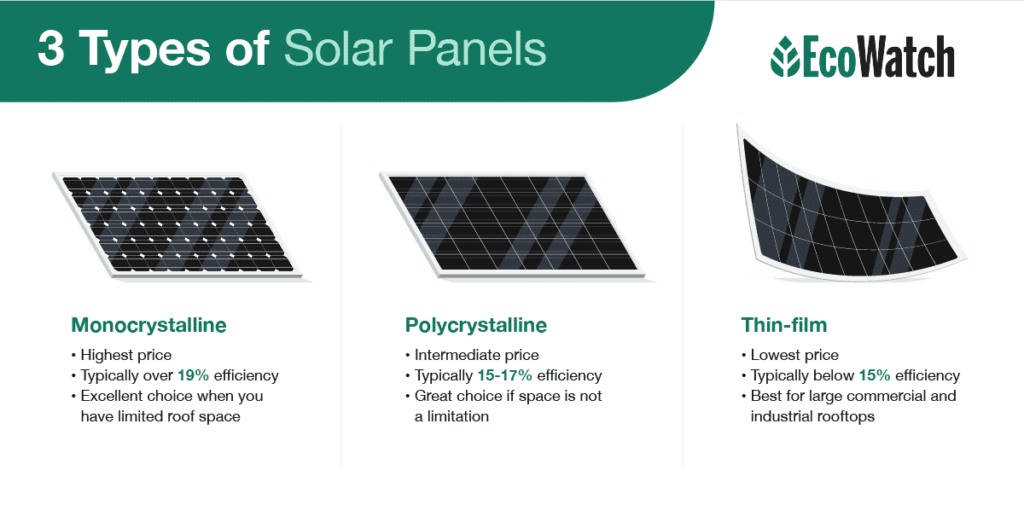

Other than their slim design, thin-film solar panels differ from traditional monocrystalline and polycrystalline panels in the materials used in production and in efficiency, but we’ll go more in-depth on this later.

SunPower

Nationwide Service

Average cost

Pros

- Most efficient panels on the market

- National coverage

- Cradle to Cradle sustainability certification

- Great warranty coverage

Cons

- Expensive

- Customer service varies by local dealer

SunPower designs and installs industry-leading residential solar and storage solutions across all 50 states. With a storied history of innovation dating back to 1985, no other company on this list can match SunPower’s experience and expertise.

SunPower earns its position as the top national installer on our list for a handful of reasons: It installs the most efficient solar technology on the residential market, offers the most expansive service area and backs its installations with a warranty well above the industry standard. All the while, SunPower pioneers sustainability efforts within the industry.

If that weren’t enough, SunPower systems come packaged with products all manufactured in-house by its sister company, Maxeon. This means that your panels, solar cells, inverters, battery and EV chargers are designed to work together and are all covered under the same warranty.

SunPower’s biggest downside? Its high-efficiency panels are considerably more expensive than most of its competitors’ products. However, its powerful panels are workhorses that make up for the initial cost with more backend production (think about this like spending more money for a car that gets more miles per gallon).

Facts and Figures: SunPower

| EcoWatch Rating |

|---|

| Better Business Bureau (BBB) Rating |

| Year Founded |

| Average Cost ($-$$$$$) |

| Solar Services |

| Brands of Solar Equipment Offered |

| Warranty Coverage |

| 5 |

| A+ |

| 1985 |

| $$$$ |

| Solar Panels, Solar Batteries, EV Chargers, System Monitoring |

| SunPower Panels |

| 25-year all-inclusive warranty |

Blue Raven Solar

Regional Service

Average cost

Pros

- Industry-leading in-house financing

- Competitive pricing

- Excellent reputation

Cons

- Doesn't offer solar batteries (coming 2022)

We like Blue Raven Solar because it understands that, for most homeowners, the cost of solar presents the biggest barrier to entry.

For that reason, Blue Raven Solar developed an innovative solar financing plan that offers in-house, flexible, zero-money-down options. The results speak for themselves, as Blue Raven Solar is now one of the fastest-growing solar companies in the nation and was recently acquired by SunPower. Its BluePower Plus+ plan (exclusive to Blue Raven) mimics the flexible structure of a lease while still providing the greatest benefits of owning your system.

Eligible homeowners enjoy 18 months of solar power before having to pay their first bill. When coupled with the federal solar investment tax credit (ITC), the initial energy savings can offset more than a third of the overall cost of a system before requiring a dollar down.

In contrast, other installers can only offer similar financing through solar leases, PPAs or third-party providers (such as Mosaic or Sunlight). Third-party loan providers can complicate the process, while opting for a loan or PPA will disqualify you from some of solar’s biggest benefits (additional property value, federal solar tax credit and local solar incentives).

Facts and Figures: Blue Raven Solar

| EcoWatch Rating |

|---|

| Better Business Bureau (BBB) Rating |

| Year Founded |

| Average Cost ($-$$$$$) |

| Solar Services |

| Brands of Solar Equipment Offered |

| Warranty Coverage |

| 4.5 |

| A+ |

| 2014 |

| $$ |

| Solar Panels, System Monitoring |

| Trina Solar, Canadian Solar, SolarEdge, Silfab, SunPower |

| 25-year manufacturer warranty; 10-year workmanship warranty, 2-year production guarantee |

How Efficient Are Thin-Film Panels?

While thin-film solar panels are cheaper than monocrystalline and polycrystalline silicon panels, they are much less efficient and have lower power capacity. Efficiency has been these panels’ biggest challenge and varies between the types of thin-film photovoltaic panels, but it has improved over time.

In 2015, Solar Frontier, the world’s largest copper indium selenium (CIS) solar energy provider, achieved a 22.3% conversion efficiency. This was a 0.6% increase over the industry’s previous record, but most thin-film solar substrates range from 6% to 18% efficiency.

Though these aren’t available to consumers, Recent solar news explains researchers from the Fraunhofer Institute for Solar Energy Systems were able to achieve a record 68.9% efficiency of gallium arsenide (GaAs) panels under laser light. Here are the four most common types of thin-film solar panels and their efficiency ratings:

- Amorphous silicon (a-Si) panels: 7% efficient

- Cadmium telluride (CdTe) panels: 9% to 15% efficient, with the highest lab test hitting 18.3%

- Copper indium gallium diselenide (CIGS) panels: 12% to 14% efficient, with tests in Germany hitting 23%

- Organic photovoltaic (OPV) panels: 18.2% efficient

Check out this video to learn more about thin-film solar cells and how you could benefit from them.

Types of Thin-Film Solar Cells

As discussed, there are several types of thin-film solar panels. Each is made from different materials, which affect the overall cost and efficiency of the panels. However, all thin-film panels contain photovoltaic material, a conductive sheet and a protective layer. Let’s take a closer look at the four most common types of thin-film solar cells:

Amorphous Solar Panels

Amorphous silicon (a-Si) solar is the oldest film-thin technology, making it the most well-developed type of thin-film PV tech. This non-toxic panel uses a chemical vapor deposition to place a thin silicon layer onto the glass, plastic or metal base.

Amorphous panels absorb a wide range of the light spectrum and perform well in low light. They can also be bent, making them less susceptible to cracks. The downside to amorphous panels is that they lose efficiency quickly. Efficiency for amorphous solar cells is around 6% to 8%.

Amorphous panels are an exciting look into the future of thin-film solar technology, but due to their low efficiency, they’re not effective for the average home. Currently, a-Si PV panels only produce a third of the energy a standard solar panel can. The tech can be found used in calculators, outdoor lights and small gadgets.

| Pros of Amorphous Thin-Film Solar Panels | Cons of Amorphous Thin-Film Solar Panels |

| + Lightweight | – Lose efficiency quickly, making them unfit for the average home |

| + Low cost | – Shorter lifespan than mono and poly panels |

| + Flexible and adhesive panels available | |

| + High temperatures only have a small impact on productivity |

Cadmium Telluride (CdTe) Panels

While amorphous silicon solar cells are the most well-developed, cadmium telluride (CdTe) panels are the most common type of thin-film modules available.These panels are actually the second most used type in the world, after crystalline silicon (c-Si) cells.

Just as the name suggests, these cells are made with cadmium telluride, a chemical compound that is effective at capturing and converting sunlight into energy. CdTe panels are less expensive than standard silicon thin-film cells and have the quickest payback time of any other thin-film panels on the market today.

Another benefit is that the cadmium telluride panels have the smallest carbon footprint of all film-thin panels available to consumers. Unfortunately, the huge problem with these solar panels is that they contain a large amount of cadmium, which is a toxic element. Special precautions need to be taken in order to deal with that component.

The panels are not harmful to humans or the environment during the manufacturing process or when being used to generate electricity on rooftops, but disposal of old panels continues to be of concern. Telluride is also very rare to find, which makes it difficult to mass-produce the technology.

| Pros of Cadmium Telluride Thin-Film Solar Panels | Cons of Cadmium Telluride Thin-Film Solar Panels |

| + Absorbing layers are great at converting energy | – Large amounts of toxic element cadmium |

| + Less expensive and quickest payback time compared to standard cells | – Telluride is a difficult element to find, which is a key component in manufacturing |

| + Smallest carbon footprint |

Copper Indium Gallium Diselenide (CIGS) Solar Panels

Copper indium gallium selenide (CIGS) thin-film panels (try saying that five times fast!) are made by placing layers of copper, indium, gallium and diselenide on top of each other within conductive layers to create a powerful semiconductor. It can go on top of glass, plastic, steel or aluminum, depending on the desired use.

With such flexible backings, the thin layers can be used in a variety of ways that typical solar technology can’t. CIGS thin-film is a very efficient technology, with some efficiencies exceeding 20% in lab tests. Unfortunately, many CIGS panels also use cadmium — the toxic chemical found in cadmium telluride (CdTe) panels.

However, some current CIGS cells have swapped the chemical for eco-friendlier zinc oxides. Overall, the biggest disadvantage is found in the price tag. CIGS panels are still very expensive to produce, making it difficult for them to compete with CdTe or silicon solar panels.

| Pros of CIGS Thin-Film Solar Panels | Cons of CIGS Thin-Film Solar Panels |

| + Very efficient film-thin panel | – Very expensive to produce |

| + Some panels are using zinc in place of cadmium | – Most contain toxic chemical cadmium |

| + High efficiency ratings |

If you want to get started right away, click one of the buttons below to connect with a pre-vetted installer.

Organic Photovoltaic (OPV) Solar Panels

The final type of thin-film solar panel is the organic photovoltaic (OPV) panel, which uses conductive organic polymers or small organic molecules in order to produce electricity. In these photovoltaic cells, several layers of thin organic vapor or solutions are placed between two electrodes to carry an electrical current.

The organic materials used are abundant, which gives the technology a lower price tag from manufacturing to market cost. Due to the variability in absorbers, OPV panels can be a range of colors — including transparent — which makes it the go-to solar module for any aesthetic needs. Despite the excitement over its aesthetic possibilities, OPV solar struggles with efficiency.

Typical cell efficiency is around 11%, which hampers its ability to be used in larger-scale operations. OPV also has a shorter lifespan than traditional and other thin-film technology currently on the market, and cell degradation is an ongoing struggle for organic PV cells.

| Pros of OPV Thin-Film Solar Panels | Cons of OPV Thin-Film Solar Panels |

| + Organic materials used in production | – Shorter lifespan |

| + Cheaper cost | – Low efficiency |

| + Aesthetic options |

Thin-Film vs Traditional Solar Panels

The biggest difference between thin-film and traditional solar panels is that thin-film panels are not divided into cells like polycrystalline and monocrystalline modules. Instead of small silicon wafers, the entire surface has whole layers of photovoltaic material.

Since these panels use material layers instead of rigid cells, they can be manufactured to be low-cost, flexible and lightweight. There are also adhesive thin-film panels, which can be used to stick onto windows and other vertical surfaces. These are popular for RV solar energy systems.

| Thin-Film | Monocrystalline | Polycrystalline | |

| Typical Efficiency | Below 15% | Over 19% | 15% to 17% |

| Cost | Lowest price | Highest price | Intermediate price |

| Temperature Coefficient | Lower temperature coefficient than mono or poly, making them efficient in heat | Lower temperature coefficient, making them more efficient in heat | Higher temperature coefficient, making them less efficient in heat |

| Intended Use | Commercial/industrial rooftops, ground-mounted solar farms, recreational vehicles, camping, portable power sources, building-integrated photovoltaics | Residential rooftop solar, especially for homes with limited space | Residential rooftop solar, especially for homes with no space limitations |

| Biggest Benefit | Lowest cost | Highest efficiency | Balanced efficiency and cost |

| Biggest Drawback | Lowest efficiency | Highest cost | Lower productivity and durability in high temperatures |

If you’re not sure which panels are right for your solar project, we recommend getting in contact with a local installer. After talking with a solar consultant, you’ll have a clear idea of which solar panels to purchase and how much they’ll cost.

Final Thoughts on Thin-Film Solar Panels

Solar thin-film panels are an exciting look into the future of flexible and mobile solar technology. While they are not yet competitive with traditional solar products, the cells are showing potential. Due to low efficiencies and larger coverage areas needed, the panels are recommended for commercial and small-scale applications as opposed to for homes.

And their low price points are appealing, but the toxicity of one of the chemicals commonly used to make them — cadmium — is a bit high and can cause environmental damage once the PV modules are disposed of.

If you want to get started right away, click one of the buttons below to connect with a pre-vetted installer.

FAQ: Thin-Film Solar Panels

Here are some frequently asked questions about thin-film solar panels. If you have specific questions that aren’t answered here, reach out to our solar power experts at solar@ecowatch.com

Thin-film panels last 10 to 20 years, which is the shortest lifespan of the three types of solar panels.19 For what they lack in lifespan, they make up for in payback period. This means after installation, the amount of money you will have saved in electricity bills will pay back the cost of the system quickly.

Every panel is made of three main parts:

- Photovoltaic material

- Conductive sheet

- Protective layer

How thin-film solar panels are made depends on the photovoltaic substrate used in manufacturing. There are four main types of PV substrates that are used:

- Cadmium telluride (CdTe)

- Amorphous silicon (a-Si)

- Copper indium gallium selenide (CIGS)

- Organic photovoltaic (OPV)

Once any of the above are placed between a conductive material and a layer of glass or plastic, the solar panel is ready to generate electricity.

When compared to monocrystalline and polycrystalline solar technology, thin-film has the lowest cost per panel. The specific price of a thin-film panel will depend on the brand and model. If you’re having an array installed, also keep in mind that your total installed cost of solar will include labor as well as components like inverters, racking, wiring and circuit breakers. Check out our article on the cost of solar panels to learn more.

Thin-film panels generally have a lower efficiency than monocrystalline and polycrystalline panels, which means you’ll need to cover a larger area to produce as much power as mono and poly cell technology. Therefore, thin-film panels are more suitable for large commercial and industrial rooftops or ground-mounted solar farms, where space is not a constraint.

They are not normally recommended for homes. However, if you’re looking for portable power or want flexible panels to install on something like an RV or boat canopy, thin-film panels will likely be the best for the job.

Companies like Sharp Solar and First Solar have large market shares in the thin-film solar industry. But you can get thin-film solar panels from many retailers, including on Amazon.

Comparing authorized solar partners

-

- Most efficient panels on the market

- National coverage

- Cradle to Cradle sustainability certification

- Great warranty coverage

- Expensive

- Customer service varies by local dealer

A+Best National Provider1985SunPower Panels25-year all-inclusive warranty

Having trouble deciding? Click below and use our process to receive multiple quotes instead:

233k

233k  41k

41k  Subscribe

Subscribe